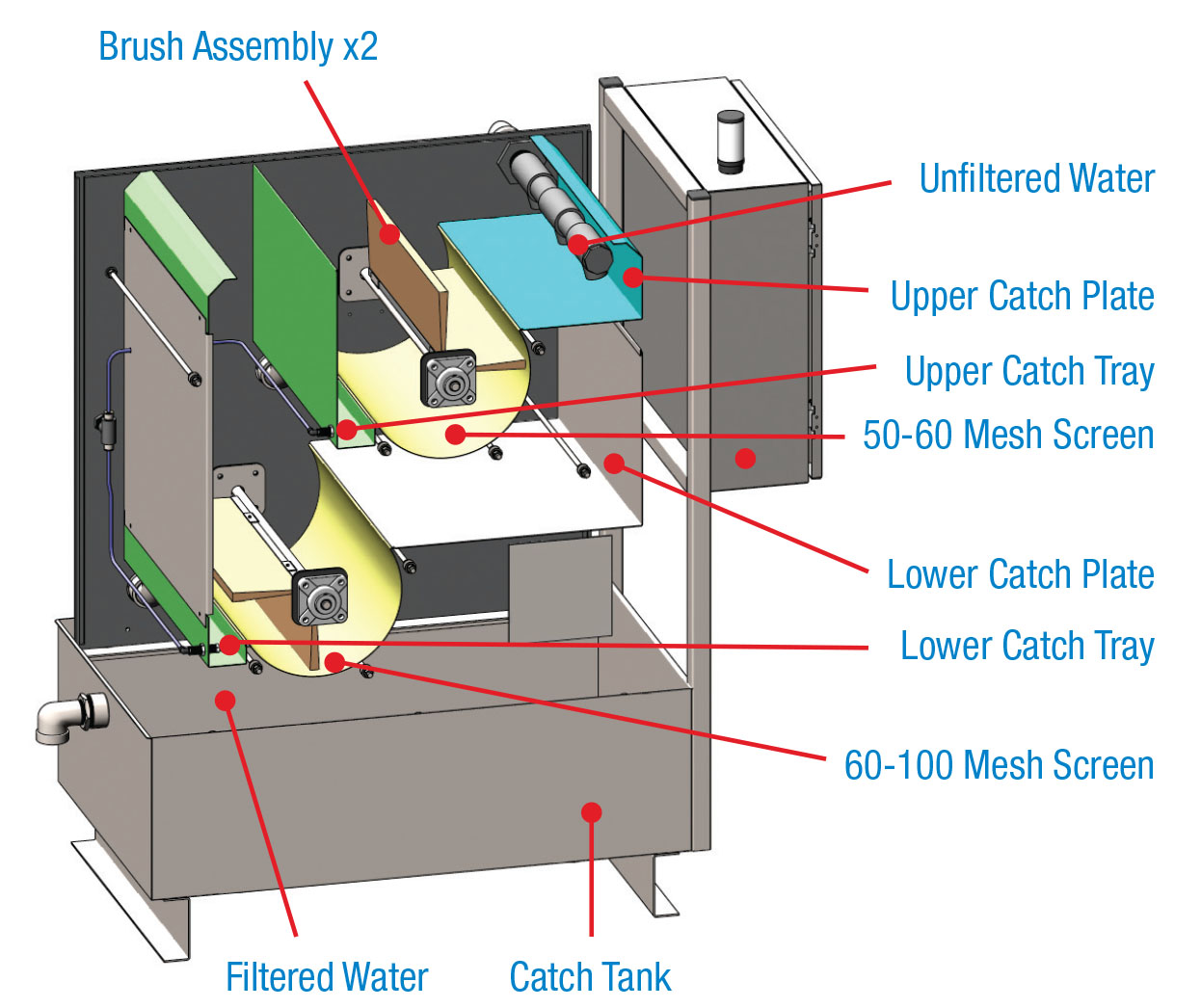

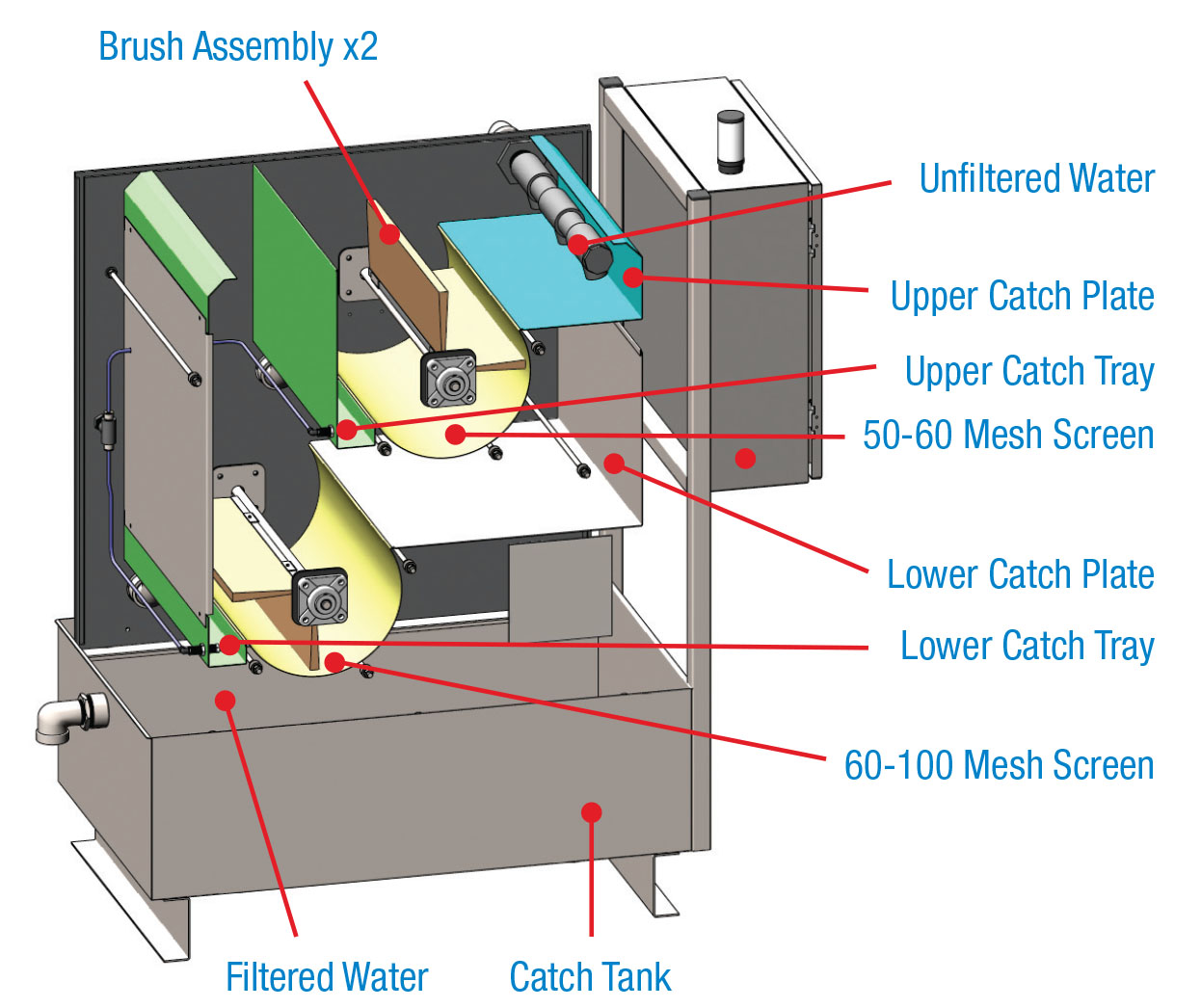

Vis-Tex Tunnel Filtration System

The Vis-Tex Tunnel Filtration System is a patent-pending technology providing an easy to install, hyper-efficient system that quickly removes debris, lint and hair from your tunnel’s water stream.

In today’s modern tunnel operations, manufacturers and laundry management have included or installed modifications that allow for a significant reduction in the use of fresh water. This is a major benefit not only in water and sewer cost reductions, but also significant savings in energy costs. But reduced water usage means an increase in soil and insolubles in the wash and rinse water streams. Hair, lint and other debris have become a greater problem. Now Gurtler has the solution… The exclusively engineered and designed, patent pending: Vis-Tex Tunnel Filtration System. This low maintenance, automatic filtration system removes an incredible amount of material from your rinse-water stream, preventing it from depositing on your textiles. Gurtler’s technical experts and engineers help you determine the best placement of the system, making sure that it has the greatest effect on your quality. You supply the power source and the connection ports and Gurtler Installs and optimizes the system. Completely hassle-free installation!

Cleaner processing water means cleaner textiles!

Features

- Small footprint, install anywhere (next to tunnel, or remote)

- Designed to be picked up with forklift/pallet jack. Also mounted on casters for easy movement.

- Everything mounted on unit; just need to hook up hose, power and wire into tunnel

- PLC controlled and programmable

- Runs only when tunnel is running; can stop during transfer, hold, etc.

- 220V/480V compatible

- Automatic valves prevent siphoning/draining of tunnel

- Auto-shut off/start based on catch tank level

- Variable pump speed

- Up to 80 GPM throughput (targeting minimum 2 exchanges of free water in the chamber per transfer)

- Self-cleaning mesh and collection tray

- Adjustable brush motor speed

- Quick change/customizable mesh sizes – 40 mesh to 100 mesh

- Quick change/customizable brushes

- Screens are cleaned by rotating brushes

- Adjustable speeds on brushes to optimize their effectiveness

- Brushes can be set in a home position to prevent bristles from permanently losing their shape

- Brushes have adjustable heights to maintain a consistent pressure on the screen

- Brushes are mounted in a channel which allows them to be quickly changed

Back to Injection Systems